- Patented AC-Link technology

- Uses streamlined AC-to-AC approach

- Replaces AC-to-DC-to-AC technology

- Shrinks the VFD by 60%

VIDAR Motors

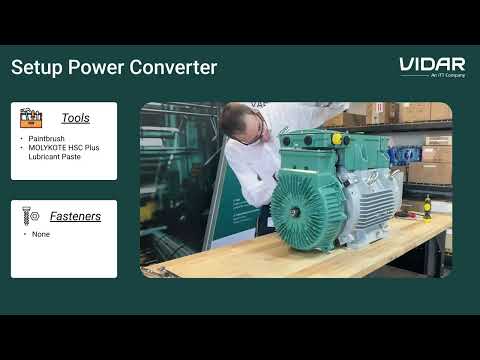

Power Converter

Motor

- Synchronous Reluctance Magnet-Assisted Motor

- Eliminates nearly all rotor losses

- Exceeds premium efficiency standards

- Operates 20-30°C cooler

- Extends motor lifespan

Rated for Severe Duty

- Purpose-built for industrial facilities

- Standard NEMA dimensions

- Designed using IEEE-841 motor standards

- Class 1 Division 2 for hazardous areas

- Meets IEEE-519 power quality standards

Terminal Box

- IP66 protection

- Standard F3 configuration

- Optional F1 or F2 terminal box

- Standard EMC filter EN55011 Class A: C3

Control Box

- IP66 protection

- Standard I/O (2 AO/AI, 6 Digital Ins, 2 Digital Outs)

- Safe torque off (STO) SIL 2

- Standard Ethernet IP and Modbus TCP

- Universal pluggable keypad

VIDAR embeds variable-speed intelligence directly into the motor, eliminating inefficient, failure-prone systems that rely on throttled valves and dampers. Unlike traditional VFD and motor setups, it requires no special inverter-duty wire, additional enclosures, or extra floor space.

One-to-one replacement

VIDAR installs seamlessly into the footprint of a conventional NEMA motor.

Unmatched efficiency

VIDAR uses only the energy required for the job, cutting energy consumption and CO2 emissions by up to 50%.

Precision control

VIDAR adapts to variable demands, giving plant managers unparalleled flexibility.

Customer-centric design

From easy installation to modular repairs, VIDAR was built for the people who use it.

Durability and reliability

Designed to thrive in harsh outdoor industrial environments, VIDAR meets stringent industrial reliability and safety standards.

| OUTPUT HP | BASE SPEED RPM | MAX. SPEED RPM | FRAME NEMA | PRODUCT NUMBER | "C" DIM IN | INPUT CURRENT AMPS | INPUT THDI % | MOTOR EFF. % | PDS* EFF. % | POWER FACTOR | WEIGHT LBS |

| 20 | 3600 | 4500 | 254/6T | EMDX020H36EXS3ABAA | 28.32 | 20.1 | < 5 | 93.6 | 90.6 | 0.99 | 364 |

| 20/10 | 1800/1200 | 2500 | 254/6T | EMDX020H18EXS3ABAA | 28.32 | 20.3/10.4 | <5 | 93.8 | 90.8 | 0.99 | 321 |

| 25 | 3600 | 4500 | 284/6TS | EMDX025H36EXS3ABAA | 30.30 | 25.2 | < 5 | 94.3 | 91.1 | 0.99 | 459 |

| 25/15 | 1800/1200 | 2500 | 284/6T | EMDX025H18EXS3ABAA | 31.67 | 25.1/15.6 | < 5 | 94.8 | 91.9 | 0.99 | 507 |

| 30 | 3600 | 4500 | 284/6TS | EMDX030H36EXS3ABAA | 30.30 | 30.3 | < 5 | 94.4 | 91.2 | 0.99 | 507 |

| 30/20 | 1800/1200 | 2500 | 284/6T | EMDX030H18EXS3ABAA | 31.67 | 30.1/20.8 | < 5 | 94.9 | 92.0 | 0.99 | 551 |

| 40 | 3600 | 4500 | 324/6TS | EMDX040H36EXS3ABAA | 33.74 | 40.2 | < 5 | 95.5 | 92.2 | 0.99 | 551 |

| 40/25 | 1800/1200 | 2500 | 324/6T | EMDX040H18EXS3ABAA | 35.24 | 40.1/26.0 | < 5 | 95.8 | 92.6 | 0.99 | 635 |

| 50 | 3600 | 4500 | 324/6TS | EMDX050H36EXS3ABAA | 33.74 | 50.2 | < 5 | 95.7 | 92.4 | 0.99 | 633 |

| 50/30 | 1800/1200 | 2500 | 324/6T | EMDX050H18EXS3ABAA | 35.24 | 50.1/31.2 | < 5 | 96.0 | 92.8 | 0.99 | 716 |

| 60 | 3600 | 4500 | 364/5TS | EMDX060H36EXS3ABAA | 36.25 | 60.6 | < 5 | 96.1 | 92.6 | 0.99 | 800 |

| 60/40 | 1800/1200 | 2500 | 364/5T | EMDX060H18EXS3ABAA | 38.37 | 60.3/41.6 | < 5 | 95.8 | 93.3 | 0.99 | 890 |

| 75 | 3600 | 4500 | 364/5TS | EMDX075H36EXS3ABAA | 36.25 | 75.5 | < 5 | 96.2 | 93.1 | 0.99 | 888 |

| 75/50 | 1800/1200 | 2500 | 364/5T | EMDX075H18EXS3ABAA | 38.37 | 75.4/51.5 | < 5 | 95.9 | 93.4 | 0.99 | 981 |

Motor Specifications:

Power Converter:

- Direct AC to AC power conversion

- No electrolytic capacitors needed

- Singling cooling fan for the converter and motor

Motor:

- Synchronous Reluctance Magnet-Assisted

- Exceeds NEMA premium efficiency standards

- Operates 10-25% cooler

Output Power:

- 15-75 hp at 460V

Input Power:

- Operates at less than 5% THDi

- Meets IEEE-519 standards

- 0.99 power factor

Speed Range:

- 3600rpm base model operation from 360 to 4500rpm

- 1800rpm base model operation from 180 to 2500rpm

Severe Duty:

- Designed using IEEE-841 specifications

- Rated for Class I, Division 2, environments

Dimensions:

- Drop-in replacement for a NEMA frame induction motor

- “C” Length 4 to 6 inches longer

Installation:

- No additional MCC space required

- No shielded VFD cable or motor output filters needed

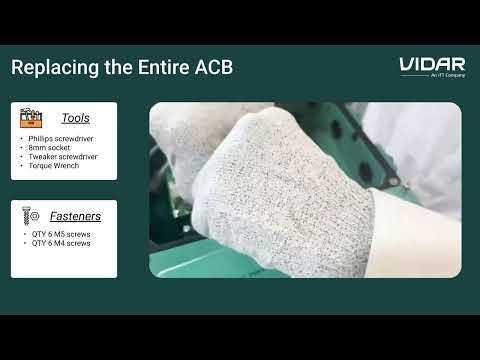

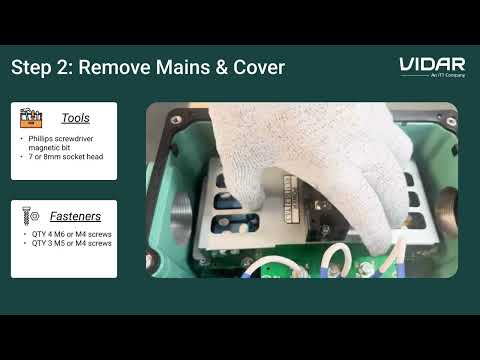

Maintenance:

- Modular design for easy maintenance

- Power converter replacement in under an hour

- Replaceable motor module, bearings, and seal

Universal Interface:

- Compatible with PLCs, SCADA, and DCS systems

- Plug-in keyboard for programming

- Standard analog and digital I/O

- Standard ethernet IP/Modbus TCP

Training Videos

VIDAR Control Board Replacements

VIDAR AC LINK Converter Replacement

VIDAR Replacing EMI Filter and MOVs